Other Polyurethane Parts

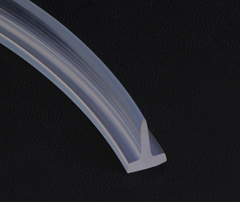

Shanghai Pepsen manufactures standard and custom extruded TPU T

profiled squeegee as per customer requirements including drawings or

samples. Hardness is usually 80A-85A, but can vary as well as color.

Shanghai Pepsen manufactures standard and custom extruded TPU T

profiled squeegee as per customer requirements including drawings or

samples. Hardness is usually 80A-85A, but can vary as well as color.

What is extruded

TPU T profiled squeegee?

TPU is abbreviation

of thermoplastic PU, it is called so comparing to thermoset polyurethane. They

have big difference in the view of inner structure and have their own

advantages and disadvantages. TPU has better liner properties such as elongation

at break and resilience, so they are widely used as transmission belt and long

products. TPU exists in the form of granules, they can be melted, then be

extruded or injection molded .T profiled squeegee is made by TPU extruder. They

are widely used for rotary screen printing machines.

What are

advantages of extruded TPU T profiled squeegee?

Super

abrasion resistance.

Excellent resilience

Impact and

shock absorption.

Oil and Solvent

resistant

FDA accepted

Many tools

in stock to avoid high tooling cost.

How did

PEPSEN develop custom extruded TPU T profiled squeegee?

A tool is necessary

for TPU extrusion. Once we design and build a tool, we need to start the TPU

extruder and test the tool, usually the tool needs to be tested and revised for

2-3 times before we can get all dimensions within tolerance. Thus, tooling cost

is only a small portion of sampling cost, the cost for 2-3 times tool testing

is the main cost.

Before each extruding,

there are fixed charges such as preheating cost, cost of raw material used to

clean the extruder and raw material used to adjust tool. That is why TPU extruding

is only cost effective for big volume products.