The differences between polyurethane rubber coated rollers and other materials

Polyurethane material is a kind of high molecular

material with excellent mechanical properties formed by the polycondensation

reaction of polyols and isocyanates, and it has strong plasticity.

Polyurethane material is a kind of high molecular

material with excellent mechanical properties formed by the polycondensation

reaction of polyols and isocyanates, and it has strong plasticity.

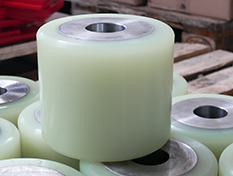

Polyurethane materials are widely used in applications. Among them, polyurethane rubber-coated rollers also adopt polyurethane materials. For rubber rollers, Polyurethane rubber-coated rollers have quite obvious differences from rubber rollers made of other materials. Next, let's take a look at the differences between polyurethane rubber-coated rollers and rubber rollers made of other materials.

The differences between polyurethane material and other materials:

1. Wear resistance: Polyurethane rubber rollers have excellent wear resistance and can maintain a long service life under high loads and frequent use. In contrast, the wear resistance of ordinary rubber rollers is relatively poor, and they are prone to wear, resulting in a shorter replacement cycle.

2. Hardness: The hardness range of polyurethane rubber rollers is wide. Different hardness levels can be adjusted by changing the formula to meet various application requirements. However, the hardness range of ordinary rubber rollers is relatively narrow, and the flexibility for adjusting hardness is relatively low.

3. Elasticity and recoverability : Polyurethane rollers have good elasticity and recoverability, and can return to their original shape within a certain period of time after being compressed or deformed. The elasticity and recoverability of ordinary rollers are slightly inferior to those of polyurethane, and they are prone to deformation after long-term use.

4. Polyurethane rubber rollers have a certain degree of corrosion resistance and are suitable for use in environments with certain corrosiveness. The chemical corrosion resistance of ordinary rubber rollers is relatively poor and they are easily eroded by solvents and chemicals.

5. Mechanical properties : Polyurethane rubber rollers have high strength and excellent load-bearing capacity, capable of withstanding large loads and impacts; The strength and load-bearing capacity of ordinary material rubber rollers are relatively low, and they are prone to damage under high load conditions.

6. Temperature resistance : Polyurethane rubber rollers can maintain stable performance within a certain temperature range. The temperature resistance of ordinary rubber rollers is poor. They tend to soften at high temperatures and become brittle at low temperatures .

The above are the differences between polyurethane rubber-coated rollers and rubber rollers made of other materials. Compared with them, polyurethane rubber-coated rollers are superior to rubber rollers made of other materials in terms of wear resistance, hardness, elasticity and recovery. However, when choosing the material of the rubber roller, a comprehensive consideration should be made based on one's own usage environment, parameters and other aspects.