Production process of casting molded urethane products

Manual

batch method

Manual

batch method

This method is a more commonly used method in laboratory

and batch production. The commonly used oligomer polyol/TDI/MOCA system

operation process is to weigh an appropriate amount of prepolymer in a

container of appropriate size, heat it to 80-90°C under stirring, and place it in a vacuum dryer to degas

5~ 20min,

then add melted MOCA and other chain extenders, stir and mix evenly (1~2min), if necessary, perform secondary defoaming (2~3min), then pour into the prepared mold, heat to vulcanize

or wait for gel When molding and curing. For large products, mixing and

degassing in the reactor can be used, and then pouring and forming. The

advantage of this method is less investment, but the disadvantage is that the

rubber has high viscosity, short pouring time, easy to entrain bubbles,

difficult to mix uniformly, low production efficiency, high labor intensity,

and it is only suitable for small-scale production of small and medium-sized

products.

Mechanical

continuous method

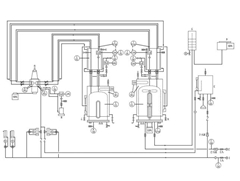

This method uses the casting machine as the main

equipment. The preheating and defoaming of the prepolymer, the melting of the

chain extender (such as MOCA), and the metering, mixing and pouring of the

prepolymer and the chain extender are all in the casting machine. Continuous

completion. The operation of heating, metering, mixing, pouring, cleaning and

stopping driving of materials can also be automatically controlled by the

computer, which can continuously produce CPU products. This method is widely

used in the polyurethane industry. Its advantages are stable product quality

and high production efficiency, suitable for the production of large and

medium-sized products and mass products. The production device is shown in the

figure.